The United States Food and Drug Administration (FDA) has released a finalised guidance document titled “Q9(R1) Quality Risk Management,” prepared under the direction of the International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH). This document is a targeted revision of the 2006 guidance on Quality Risk Management (QRM) and addresses critical issues that have emerged over the years, particularly concerning product availability risks related to manufacturing quality issues, a lack of understanding regarding the formality required in QRM, and the high levels of subjectivity often seen in risk assessments. This updated guidance aims to clarify QRM principles and tools that can be applied across various pharmaceutical quality processes. The revision replaces the draft guidance “Q9(R1) Quality Risk Management” issued on June 15, 2022.

Introduction

The FDA, as part of its ongoing commitment to enhancing pharmaceutical quality, has announced the availability of a finalised guidance document titled “Q9(R1) Quality Risk Management.” This guidance was developed under the umbrella of the International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH), a global organisation that brings together regulatory authorities and the pharmaceutical industry to discuss scientific and technical aspects of drug development.

The revised guidance builds upon the original Q9 guidance issued in 2006. The updates reflect advancements in the industry and address some of the shortcomings in the earlier version, such as challenges in risk-based decision-making, a lack of clarity around the formal structure of QRM processes, and the subjectivity often encountered in risk assessments. This updated document also provides improved tools and methodologies to manage product availability risks stemming from manufacturing quality issues.

The goal of the updated guidance is to provide a clearer framework for pharmaceutical companies to follow, ensuring that their QRM practices are robust, consistent, and effective. These revisions are essential to help mitigate risks associated with drug production and to enhance overall patient safety by ensuring the availability of high-quality pharmaceuticals.

Overview of the Guidance

The Q9(R1) Quality Risk Management guidance is divided into several key sections, each focusing on a different aspect of QRM. These sections outline the principles of QRM, the tools available for implementing effective risk management strategies, and the applications of QRM within the pharmaceutical industry. Below is an overview of the key sections and updates provided in the Q9(R1) revision.

Principles of Quality Risk Management

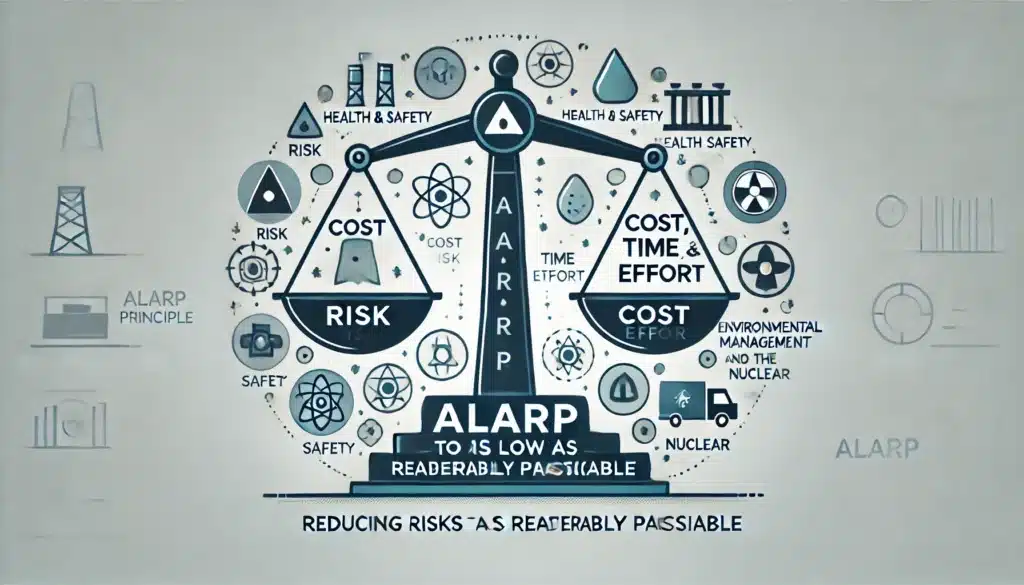

The core principle of QRM is that the level of effort, formality, and documentation of the QRM process should be commensurate with the level of risk. This means that higher-risk processes or products require more formal and detailed risk management procedures, while lower-risk areas may need a less formal approach.

The updated guidance reinforces the importance of a systematic process for assessing, controlling, communicating, and reviewing risks to the quality of drug products across their lifecycle. This includes understanding that risk management should be an integral part of the pharmaceutical quality system, from development through manufacturing to distribution.

Enhancements to Risk-Based Decision-Making

One of the major updates in the Q9(R1) guidance focuses on improving risk-based decision-making within QRM. The original guidance from 2006 was criticised for being vague in this area, leading to inconsistent application across the industry.

The revised guidance provides more detailed recommendations on how to incorporate risk-based decision-making into all aspects of QRM. It stresses that decisions should not be based solely on qualitative assessments but should also incorporate quantitative data wherever possible to provide a more objective and measurable approach to managing risks.

The revision also provides clearer guidelines on how to document the rationale behind risk-based decisions, ensuring that there is transparency and accountability throughout the QRM process.

Addressing Subjectivity in Risk Assessments

Subjectivity in risk assessments has been a long-standing issue within QRM, with different stakeholders often having varying perspectives on what constitutes an acceptable level of risk. The revised guidance takes steps to address this by providing more objective criteria for assessing risk and defining clear thresholds for different levels of risk.

The guidance encourages the use of structured tools such as Failure Mode and Effects Analysis (FMEA) and Hazard Analysis and Critical Control Points (HACCP) to minimise subjectivity and ensure that risk assessments are based on consistent criteria.

Furthermore, the updated document highlights the importance of using historical data and past experiences to inform risk assessments, helping to ensure that decisions are grounded in real-world evidence rather than personal opinions or assumptions.

Formality in QRM Processes

One of the key concerns addressed in the Q9(R1) revision is the lack of understanding within the industry regarding the appropriate level of formality required in QRM processes. The updated guidance provides more detailed recommendations on how to structure QRM processes, ensuring that the level of formality is appropriate for the level of risk involved.

For high-risk processes, a more formal approach is required, including detailed documentation, regular reviews, and cross-functional involvement in decision-making. For lower-risk processes, a less formal approach may be appropriate, but the guidance stresses that even in these cases, there should still be a clear rationale for the decisions made.

The guidance also highlights the importance of maintaining flexibility in QRM processes, allowing companies to adapt their approach to different situations while ensuring that the fundamental principles of QRM are adhered to.

Product Availability Risks due to Manufacturing Quality Issues

The revised guidance places a strong emphasis on addressing product availability risks that can arise from manufacturing quality issues. This is particularly important in the context of the global pharmaceutical supply chain, where disruptions to production can have serious consequences for patient care.

The guidance outlines specific strategies for managing these risks, including proactive risk assessments during the manufacturing process, regular monitoring of production systems, and contingency planning to address potential disruptions.

It also stresses the importance of involving cross-functional teams in the risk management process, ensuring that all stakeholders are aware of the potential risks and are working together to mitigate them.

Application of QRM Principles

The Q9(R1) guidance provides detailed recommendations on how QRM principles can be applied to different areas of pharmaceutical quality. These include:

Development

During the drug development process, QRM principles should be applied to identify potential risks to product quality and to implement strategies to mitigate these risks. This can involve risk assessments related to formulation development, process design, and analytical method development.

Manufacturing

In the manufacturing process, QRM can be used to identify critical control points, assess potential failure modes, and implement controls to minimise the risk of quality issues. The guidance also emphasises the importance of continuous monitoring and review of manufacturing processes to ensure that risks are being effectively managed over time.

Distribution

The guidance also highlights the importance of applying QRM principles to the distribution process, where risks such as contamination, degradation, or improper storage can affect product quality. Risk assessments should be conducted to identify potential issues and appropriate controls should be implemented to mitigate these risks.

Conclusion

The finalised Q9(R1) Quality Risk Management guidance represents a significant step forward in the FDA’s efforts to improve pharmaceutical quality management. By addressing key issues such as risk-based decision-making, subjectivity in risk assessments, and formality in QRM processes, the revised guidance provides a clearer framework for the industry to follow.

The emphasis on managing product availability risks due to manufacturing quality issues is particularly important in today’s global supply chain, where disruptions can have far-reaching consequences for patient care.

As the pharmaceutical industry continues to evolve, the principles and tools outlined in the Q9(R1) guidance will play a crucial role in ensuring that quality risk management remains a central focus, helping to safeguard the availability of safe and effective medicines for patients around the world.

The FDA’s release of this updated guidance demonstrates its ongoing commitment to promoting high standards of pharmaceutical quality, ultimately supporting public health and patient safety.

The International Council for Harmonisation (ICH) Q7 Guideline provides detailed requirements for Good Manufacturing Practice (GMP) specific to the production of active pharmaceutical ingredients (APIs). It sets out principles and standards to ensure that APIs are consistently produced and controlled to the quality standards appropriate for their intended use. The Q7 guideline addresses key areas such as personnel training, equipment qualification, process validation, and documentation to support compliance with regulatory requirements. It also covers critical aspects of quality management, including materials management, production operations, and laboratory controls, ensuring that APIs meet both safety and efficacy standards throughout their lifecycle.

Disclaimer

The information provided in this article is intended for general informational purposes only and does not constitute legal, regulatory, or professional advice. While every effort has been made to ensure the accuracy of the content at the time of publication, Open Medscience does not guarantee the completeness, reliability, or suitability of the information presented. Readers are advised to consult official sources, such as the U.S. Food and Drug Administration (FDA) or the International Council for Harmonisation (ICH), for the most up-to-date and authoritative guidance. Any actions taken based on the information in this article are strictly at the reader’s own risk. Open Medscience and its contributors disclaim all liability for any loss or damage arising from reliance on this content.