Radiopharmaceutical production involves synthesising, handling, and applying radioactive materials in medicine for diagnostic and therapeutic purposes. The unique nature of these substances presents significant environmental challenges, necessitating stringent control measures and robust compliance frameworks. This article explores the key components of environmental compliance and control in radiopharmaceutical production, addressing regulatory requirements, waste management practices, radiation protection, and the role of quality management systems. By adhering to these controls, producers can ensure that radiopharmaceuticals are manufactured and used safely, with minimal environmental impact.

Introduction

Radiopharmaceuticals are a critical component of modern medicine, used primarily for imaging and therapeutic purposes. These substances contain radioactive isotopes, which require special handling due to their potential health and environmental hazards. Ensuring environmental compliance and control in radiopharmaceutical production is crucial to protect public health and the environment from the risks associated with radioactivity.

International, regional, and national bodies tightly regulate the production of radiopharmaceuticals to ensure that all operations meet stringent safety and environmental standards. This paper will discuss the various aspects of environmental compliance and control in radiopharmaceutical production, focusing on regulatory frameworks, waste management, radiation protection, and the integration of quality management systems.

Regulatory Frameworks

A complex network of regulations governs environmental compliance in radiopharmaceutical production. These regulations are designed to ensure that all aspects of radiopharmaceutical production, from raw material procurement to waste disposal, are managed to minimise environmental and health risks. This includes understanding what are sharps and how to properly handle them, as they pose specific hazards that must be addressed in compliance protocols.

International Guidelines

At the international level, the International Atomic Energy Agency (IAEA) plays a key role in establishing standards for the safe production and use of radioactive materials. The IAEA’s safety standards provide a comprehensive framework for radiation protection, waste management, and environmental monitoring. National regulatory bodies often adopt or adapt these guidelines to fit local contexts.

European and UK Regulations

In Europe, the Euratom Treaty and associated directives provide the overarching legal framework for the control of radioactive substances. The UK has integrated these directives into its national legislation as a signatory. UK legislation includes the Ionising Radiations Regulations 2017 (IRR17) and the Environmental Permitting (England and Wales) Regulations 2016, which provide detailed requirements for radiation protection and environmental control.

National and Local Regulations

At the national and local levels, specific regulations address the environmental impact of radiopharmaceutical production. These include licensing requirements, waste disposal regulations, and radiation protection standards. Regulatory agencies, such as the Environment Agency in England, oversee compliance with these regulations, conducting inspections and enforcing penalties for non-compliance.

Waste Management in Radiopharmaceutical Production

One of the most critical aspects of environmental compliance in radiopharmaceutical production is the management of radioactive waste. Radiopharmaceutical production generates various types of waste, including solid, liquid, and gaseous forms, each requiring specific handling and disposal methods.

Types of Radioactive Waste

Radioactive waste is classified according to its radioactivity level, half-life, and form. The main categories include low-level waste (LLW), intermediate-level waste (ILW), and high-level waste (HLW). LLW and ILW are more common in radiopharmaceutical production and comprise contaminated materials, equipment, and waste solutions.

Waste Minimisation Strategies

Minimising the generation of radioactive waste is a key objective in radiopharmaceutical production. Techniques such as process optimisation, careful planning of production schedules, and the use of advanced technologies can reduce the volume of waste generated. Additionally, recycling and reusing materials where possible also contribute to waste minimisation.

Waste Treatment and Disposal

Treatment of radioactive waste involves a range of methods, depending on the waste type. Solid waste is often compacted or incinerated, while liquid waste may undergo chemical treatment to reduce its radioactivity. Gaseous emissions are filtered and monitored to ensure they meet regulatory limits before release into the atmosphere.

Disposal of radioactive waste is strictly controlled. LLW is typically disposed of in near-surface facilities, while ILW and HLW require more secure, deep geological disposal. Compliance with disposal regulations is essential to prevent environmental contamination and protect public health.

Radiation Protection

Radiation protection is a core component of environmental control in radiopharmaceutical production. The aim is to protect workers, the public, and the environment from the harmful effects of ionising radiation.

Radiation Protection Principles

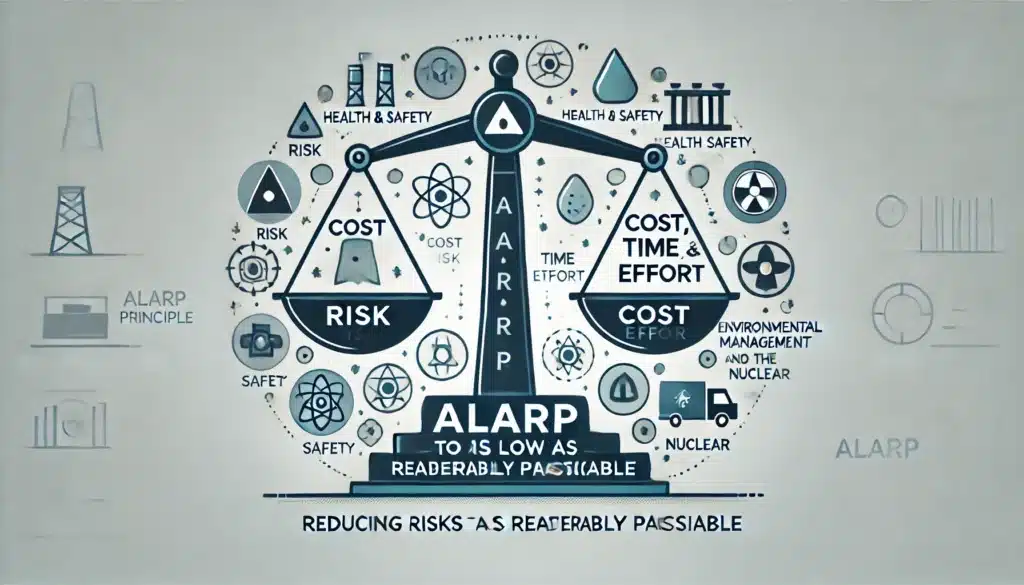

The three fundamental principles of radiation protection are justification, optimisation, and dose limitation. Justification ensures that a clear benefit warrants any exposure to radiation. Optimisation involves keeping exposures as low as reasonably achievable (ALARA), considering economic and social factors. Dose limitation sets strict limits on the maximum radiation dose that individuals can receive.

Radiation Monitoring

Regular monitoring of radiation levels is essential in radiopharmaceutical facilities. This includes personal dosimetry for workers, environmental monitoring around the facility, and equipment checks to ensure that radiation levels remain within safe limits. Automated monitoring systems are often employed to provide real-time data and alerts in case of abnormal radiation levels.

Protective Measures and Equipment

To minimise radiation exposure, personal protective equipment (PPE) such as lead aprons, gloves, and shields are standard in radiopharmaceutical production. In addition, engineering controls, such as the use of fume hoods, shielding, and remote handling tools, further reduce the risk of radiation exposure to workers.

Quality Management Systems

A robust quality management system (QMS) is integral to maintaining environmental compliance and control in radiopharmaceutical production. A QMS ensures that all processes are carried out consistently and according to established standards, reducing the risk of non-compliance and environmental incidents.

Good Manufacturing Practice (GMP)

Good Manufacturing Practice (GMP) is a set of guidelines governing pharmaceutical production, including radiopharmaceuticals. GMP covers all aspects of production, from sourcing raw materials to the final product, ensuring that every step is performed under controlled conditions to prevent contamination and ensure product quality.

Environmental Management Systems (EMS)

An Environmental Management System (EMS) is a framework that enables organisations to systematically manage their environmental responsibilities. In radiopharmaceutical production, an EMS helps ensure compliance with environmental regulations, facilitates waste reduction, and promotes continual improvement in environmental performance. ISO 14001 is an internationally recognised standard for EMS, providing a structured approach to managing environmental impacts.

Audits and Continuous Improvement

Regular audits, both internal and external, are crucial for verifying compliance with environmental regulations and QMS standards. These audits identify areas for improvement, ensuring that environmental controls are continually refined and enhanced. Continuous improvement processes are embedded in the QMS, driving ongoing optimisation of environmental performance.

Training and Competence

Environmental compliance and control in radiopharmaceutical production are highly dependent on the knowledge and competence of personnel. Ensuring that staff are properly trained in environmental and radiation safety is essential for maintaining compliance and preventing incidents.

Training Programmes

Training programmes should cover all aspects of radiopharmaceutical production, with a focus on environmental and radiation protection. These programmes should be regularly updated to reflect changes in regulations and advances in technology. Training should be tailored to different roles within the organisation, ensuring that all staff, from operators to managers, have the necessary knowledge and skills.

Competency Assessment

Assessing personnel competency is a critical component of environmental compliance. Regular assessments help identify training needs and ensure that staff are capable of performing their duties safely and effectively. Competency assessments should be documented and used to guide the development of further training programmes.

Emergency Preparedness and Response

Given the hazardous nature of radiopharmaceutical production, it is essential to have robust emergency preparedness and response plans in place. These plans are designed to protect workers, the public, and the environment in the event of an incident.

Risk Assessment

The first step in emergency preparedness is to conduct a thorough risk assessment, identifying potential hazards and their likelihood of occurrence. This assessment informs the development of emergency response plans and helps to prioritise resources for mitigating risks.

Emergency Response Plans

Emergency response plans should be comprehensive, detailing the actions to be taken in the event of various types of incidents, such as spills, leaks, or equipment failures. These plans should include procedures for evacuation, containment, and communication with regulatory authorities and the public.

Training and Drills

Regular training and drills are essential to ensure that all personnel are familiar with the emergency response plans and know how to act in an emergency. Drills should simulate different scenarios and involve all relevant staff, including emergency responders.

Environmental Monitoring and Reporting

Ongoing environmental monitoring is essential for verifying compliance with regulatory requirements and detecting any potential environmental impacts from radiopharmaceutical production. Transparent reporting practices further reinforce accountability and public trust.

Monitoring Programmes

Environmental monitoring programmes typically involve the regular collection of data on air, water, and soil quality around the production facility. These programmes are designed to detect any release of radioactive materials into the environment and to ensure that emissions remain within permissible limits.

Reporting Requirements

Regulatory agencies often require regular reporting of environmental monitoring data. These reports must be accurate, timely, and comprehensive, providing detailed information on the facility’s environmental performance. Failure to report or inaccurate reporting can result in severe penalties and loss of operating licences.

Public Disclosure and Transparency

Public disclosure of environmental performance data is becoming increasingly important. Reporting transparency helps build trust with the local community and other stakeholders. Many organisations voluntarily publish environmental reports outlining their compliance with regulations and their efforts to minimise environmental impact.

Ethical Considerations and Sustainability

The ethical dimension of environmental compliance in radiopharmaceutical production extends beyond mere regulatory adherence. It encompasses a broader commitment to sustainability and the responsible stewardship of natural resources.

Sustainable Production Practices

Sustainable production practices in radiopharmaceuticals involve using resources efficiently, minimising waste, and reducing the overall environmental footprint of the production process. This can include investing in energy-efficient technologies, reducing water usage, and sourcing materials from sustainable suppliers.

Corporate Social Responsibility (CSR)

Corporate Social Responsibility (CSR) in radiopharmaceutical production involves addressing the business’s broader social and environmental impacts. This includes engaging with local communities, investing in environmental initiatives, and ensuring that the production of radiopharmaceuticals contributes positively to society.

Future Trends and Challenges

The field of radiopharmaceutical production is continually evolving, with new technologies and regulatory requirements emerging. Staying ahead of these trends is essential for maintaining environmental compliance and control.

Advances in Technology

Advances in technology are likely to bring about significant changes in radiopharmaceutical production. New methods for waste treatment, more efficient production processes, and improved monitoring technologies will enhance environmental control. However, these advances also require ongoing regulatory frameworks and adaptation of compliance strategies.

Evolving Regulatory Landscape

The regulatory landscape for radiopharmaceutical production is dynamic, with new regulations and updates to existing laws being introduced regularly. Keeping abreast of these changes is essential for maintaining compliance. This requires a proactive approach, with organisations investing in regulatory intelligence and engaging with regulatory bodies.

Global Collaboration

Global collaboration is increasingly important in addressing the environmental challenges associated with radiopharmaceutical production. International partnerships can facilitate the sharing of best practices, harmonisation of standards, and development of innovative solutions to common challenges.

Conclusion

Environmental compliance and control in radiopharmaceutical production are critical to ensuring the safe and sustainable use of radioactive materials in medicine. Producers can minimise the environmental impact of their operations by adhering to stringent regulatory frameworks, implementing effective waste management practices, and fostering a culture of continuous improvement. As the field continues to evolve, ongoing vigilance, innovation, and collaboration will be key to meeting the environmental challenges of the future.

Disclaimer

The information provided in this article, Ensuring Environmental Compliance and Control in Radiopharmaceutical Production, is intended for general informational purposes only. It is not a substitute for professional advice, regulatory guidance, or legal consultation. While Open MedScience endeavours to ensure the accuracy and relevance of the content at the time of publication (11 August 2024), regulations and industry standards may change over time. Readers are advised to consult with qualified professionals and relevant regulatory authorities for specific guidance applicable to their circumstances. Open MedScience does not accept any responsibility for loss, damage, or liability resulting from reliance on the information contained in this article.

home » blog » regulatory affairs »