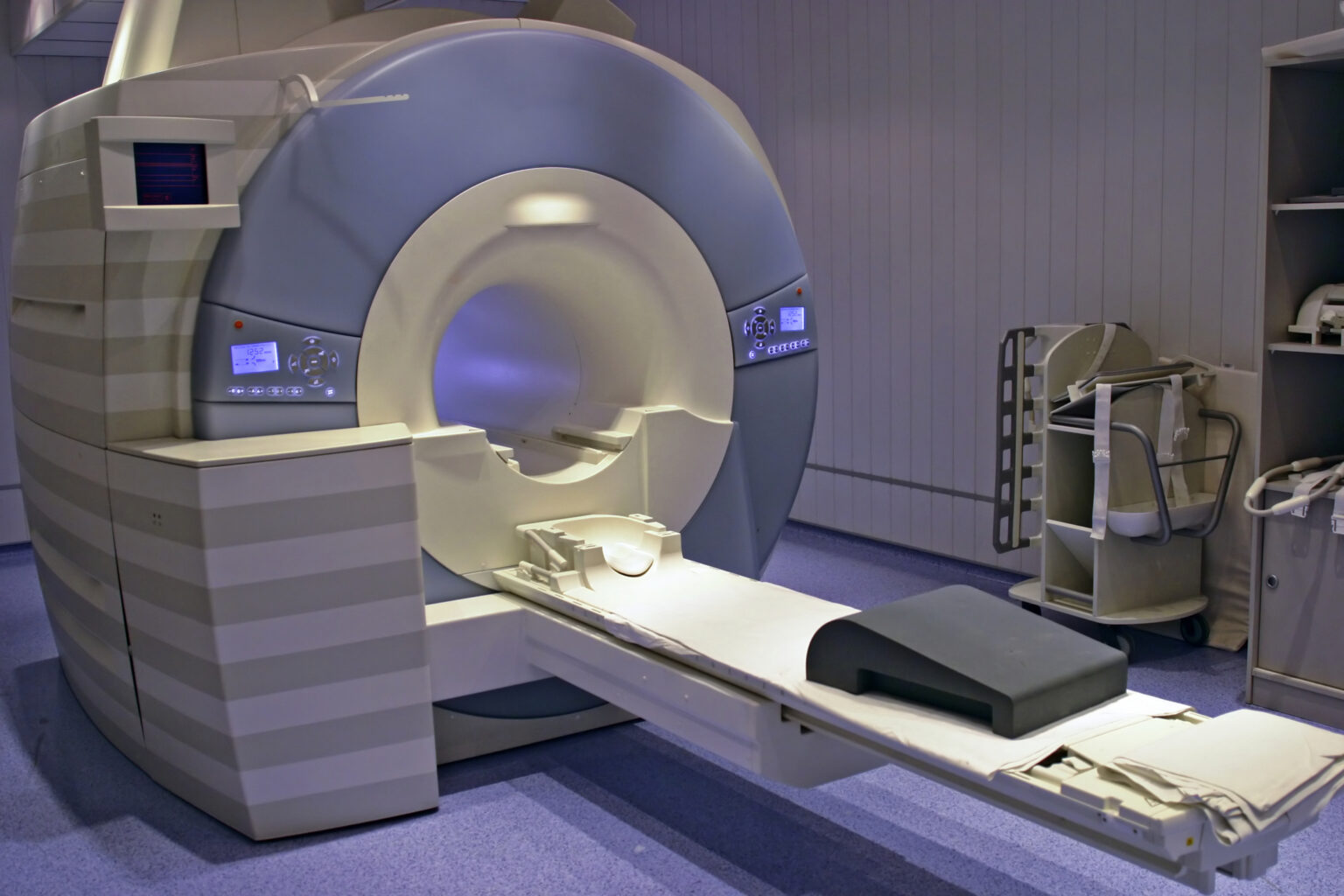

Summary: Magnetic Resonance Imaging (MRI) is a vital diagnostic tool that allows clinicians to visualise the internal structures of the human body without the use of ionising radiation. While the technology is renowned for its precision and safety, one characteristic often surprises first-time patients—the loud, rhythmic knocking or banging sounds produced during a scan. This noise is not merely incidental; it arises from the fundamental physics and engineering principles that govern MRI operation. Understanding why MRI scanners produce such loud noise requires a closer examination of their magnetic fields, gradient coils, rapid switching systems, and the methods manufacturers employ to mitigate these acoustic effects for patient comfort and optimal image quality.

Keywords: MRI scanner, gradient coils, acoustic noise, magnetic fields, patient comfort, imaging technology.

The Basics of MRI Technology

MRI scanners work by exploiting the magnetic properties of hydrogen atoms, which are abundant in the human body. The system utilises a powerful static magnetic field—typically ranging from 1.5 to 3 Tesla in clinical settings—to align these atoms. When a radiofrequency (RF) pulse is applied, the hydrogen nuclei are excited and emit signals as they return to their original alignment. These signals are detected and processed to form highly detailed images of tissues and organs.

While the static magnetic field and RF pulses are silent, the process of spatial encoding—the method used to determine where signals originate within the body—requires rapidly changing magnetic fields. These variations are produced by components known as gradient coils. It is the interaction between these coils, the main magnetic field, and mechanical forces that generates the distinctive sounds associated with MRI scanning.

The Role of Gradient Coils

The gradient coils are essential for encoding spatial information into the MRI signal. Each scanner contains three sets of gradient coils aligned along the X, Y, and Z axes. When electrical currents flow through these coils, they create small variations in the magnetic field strength across the imaging volume. These gradients allow the scanner to determine the position of each signal within the body and reconstruct an image slice by slice.

However, these coils must switch on and off rapidly—often thousands of times per second—to achieve the spatial resolution and speed required for modern imaging sequences. Each time a current changes direction, it interacts with the strong static magnetic field of the main magnet, producing Lorentz forces. These forces cause the metal structures of the coils to vibrate, and it is these vibrations that create the familiar knocking and thumping noises heard during a scan.

The Physics Behind the Sound

The relationship between the current in the gradient coils and the resulting force can be described by the Lorentz force equation, F = I × B, where F represents the force, I is the electric current, and B is the magnetic field. In the MRI environment, where the main magnetic field is extremely strong, even small changes in current can produce substantial forces.

Each rapid switching event produces a sudden mechanical movement or vibration in the gradient assembly. Because these coils are mounted in a confined space within the magnet bore, the vibrations transfer to surrounding structures, effectively turning the scanner into a resonating chamber. The frequencies of these vibrations often lie within the audible range (roughly 20 Hz to 20 kHz), creating the loud clicking and drumming patterns characteristic of MRI noise.

The specific sound pattern varies depending on the imaging sequence. For example, fast imaging techniques such as echo-planar imaging (EPI), commonly used for functional MRI (fMRI) and diffusion-weighted imaging, switch gradients at very high speeds, producing some of the loudest noises—often exceeding 110 decibels.

Factors Influencing MRI Noise Levels

Several factors contribute to the loudness of an MRI scanner for the patient. The strength of the main magnetic field plays a significant role; higher field strengths result in greater Lorentz forces and, therefore, stronger vibrations. A 3T scanner is typically noisier than a 1.5T model, though advances in coil design have somewhat mitigated this difference.

The type of imaging sequence also matters. Sequences that demand rapid gradient switching, such as diffusion-weighted or functional imaging, tend to be louder. Conversely, sequences with slower gradient transitions or those using special noise-reduction techniques produce less sound.

The scanner’s construction and acoustic insulation further influence perceived noise levels. Manufacturers now design gradient coil housings with damping materials and suspension systems to absorb vibrations. Additionally, the geometry and placement of the coils within the magnet bore influence how sound waves resonate and propagate.

Managing and Reducing MRI Noise

Although MRI noise is an inevitable by-product of its operation, several strategies exist to reduce its impact on patients and clinical staff. The most common measure is the use of ear protection. Patients are routinely given foam earplugs or over-ear defenders, which can reduce noise exposure by up to 30 decibels. In paediatric or particularly sensitive cases, active noise-cancelling headphones may also be used, sometimes integrated with communication or music playback systems to enhance the experience.

From a technical standpoint, MRI manufacturers continue to develop quieter scanning technologies. One such advancement is “Quiet MRI” or “Silent Scan,” where the gradient coils are driven in smoother, sinusoidal patterns rather than abrupt square-wave pulses. This reduces mechanical stress and lowers sound levels significantly, sometimes by as much as 70 per cent.

Another approach involves the redesign of gradient coil assemblies using composite materials that absorb rather than transmit vibration. Improved coil suspension systems, acoustic shielding, and optimised pulse sequences all contribute to quieter operation without sacrificing image quality.

Furthermore, patient positioning and the use of bore liners—foam or plastic inserts that reduce sound reflection—can help reduce the perceived loudness. Even minor improvements in scanner ergonomics and sound insulation can have a significant impact on patient comfort and cooperation during prolonged scans.

The Importance of Patient Communication

For patients undergoing MRI for the first time, the noise can be startling. Clear communication from radiographers and clinicians is essential to prevent anxiety or movement during scanning, both of which can compromise image quality. Patients are typically briefed on what to expect, including the duration of the scan, the noises they will hear, and the importance of remaining still.

In clinical practice, the acoustic environment is also considered when imaging vulnerable populations. For example, infants and children may be sedated or scanned during natural sleep, with extra measures taken to minimise exposure to noise. Neonatal MRI systems are designed with special acoustic shielding and reduced gradient performance to maintain safety while still achieving diagnostic image quality.

Understanding the source of the sound can also help patients better tolerate the procedure. When they realise that the noises correspond to normal gradient activity and do not indicate a problem with the machine, they are more likely to remain calm and cooperative throughout the scan.

Balancing Performance and Comfort

MRI development constantly seeks a balance between technological performance and patient comfort. Faster scanning techniques rely on aggressive gradient switching, which inherently increases noise. Yet, these techniques are essential for reducing scan times, improving image resolution, and capturing dynamic physiological processes. The challenge for manufacturers lies in designing hardware and software that deliver high-quality images while keeping sound within acceptable limits.

Acoustic noise is not merely a comfort issue—it has safety implications as well. Prolonged exposure to noise above 85 decibels can potentially affect hearing, though patients are usually protected through short exposure durations and mandatory ear protection. Technological innovations continue to focus on maintaining this safety margin while enhancing diagnostic efficiency.

The Future of Quieter MRI Scanning

The future of MRI technology points towards quieter and more patient-friendly systems. Advances in gradient coil materials, such as carbon-fibre composites, promise lighter, stiffer, and better-damped structures. Active vibration control systems, which utilise sensors and actuators to counteract mechanical oscillations in real-time, are being explored as potential solutions to further reduce sound.

Software innovations are also playing a key role. Adaptive scanning protocols can adjust gradient switching patterns based on the patient’s anatomy and the required image quality, thereby avoiding unnecessary rapid transitions that cause excess noise. Hybrid imaging systems, combining MRI with other modalities such as PET, are prompting a new wave of scanner designs that incorporate improved acoustic control from the outset.

In research settings, ultra-low-field MRI systems operating below 0.5 Tesla are being developed for portable and point-of-care applications. These systems inherently produce less noise because the magnetic forces involved are weaker. While their image resolution currently lags behind clinical scanners, they demonstrate a promising direction for quieter and more accessible imaging.

Ultimately, as imaging technologies evolve, so too does the emphasis on patient experience. Reducing MRI noise aligns with broader goals in medical imaging: to create diagnostic environments that are safe, efficient, and as comfortable as possible for patients of all ages.

Conclusion

The loud noise produced by an MRI scanner is an unavoidable consequence of the physical forces generated when powerful magnetic fields interact with rapidly switching electrical currents in the gradient coils. These vibrations translate into the banging, clicking, and humming sounds that characterise MRI scanning. Although the physics behind the noise is complex, the underlying cause is straightforward—mechanical motion induced by magnetic forces.

Modern MRI systems have made significant strides in reducing these acoustic effects through improved coil designs, damping materials, and software-controlled scanning sequences. Nevertheless, the balance between quiet operation and high image performance remains a key engineering challenge.

For patients, understanding the reason behind the sound helps demystify the experience, turning what might seem alarming into an expected part of a highly sophisticated imaging process. As quieter MRI technologies continue to develop, the focus on patient comfort will ensure that this indispensable diagnostic tool remains both effective and reassuring in clinical practice.

Disclaimer

The information provided in this article is intended for general educational and informational purposes only. It should not be used as a substitute for professional medical advice, diagnosis, or treatment. Readers are advised to consult a qualified healthcare professional with any questions or concerns regarding MRI procedures or medical imaging. Open MedScience and the author are not responsible for any actions taken based on the content of this publication.