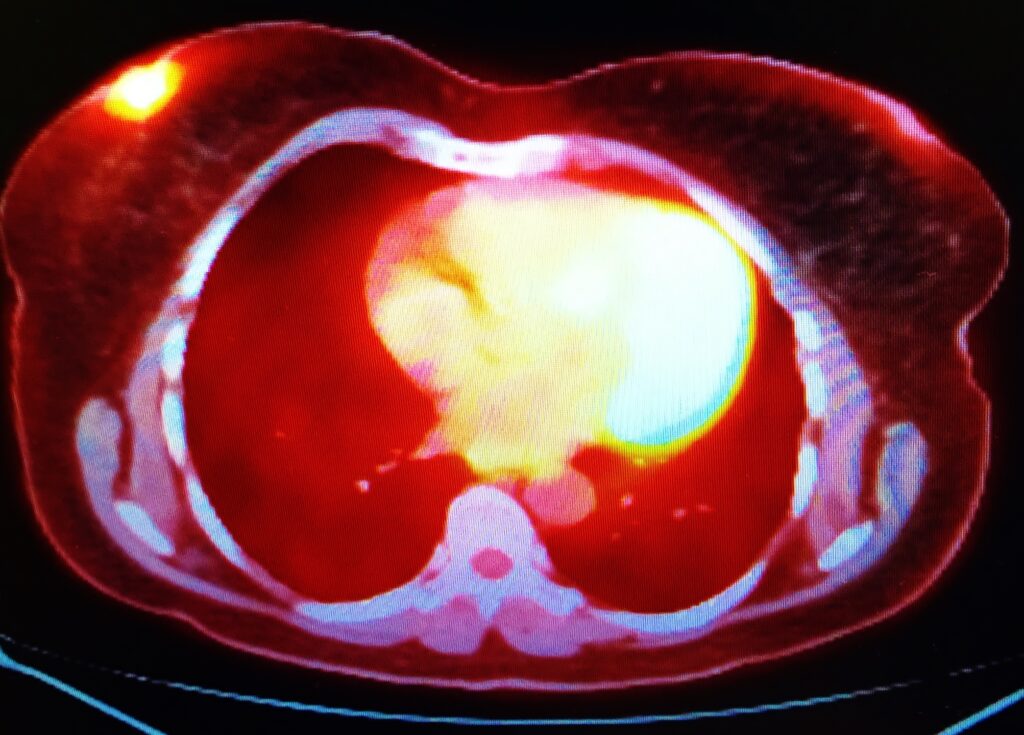

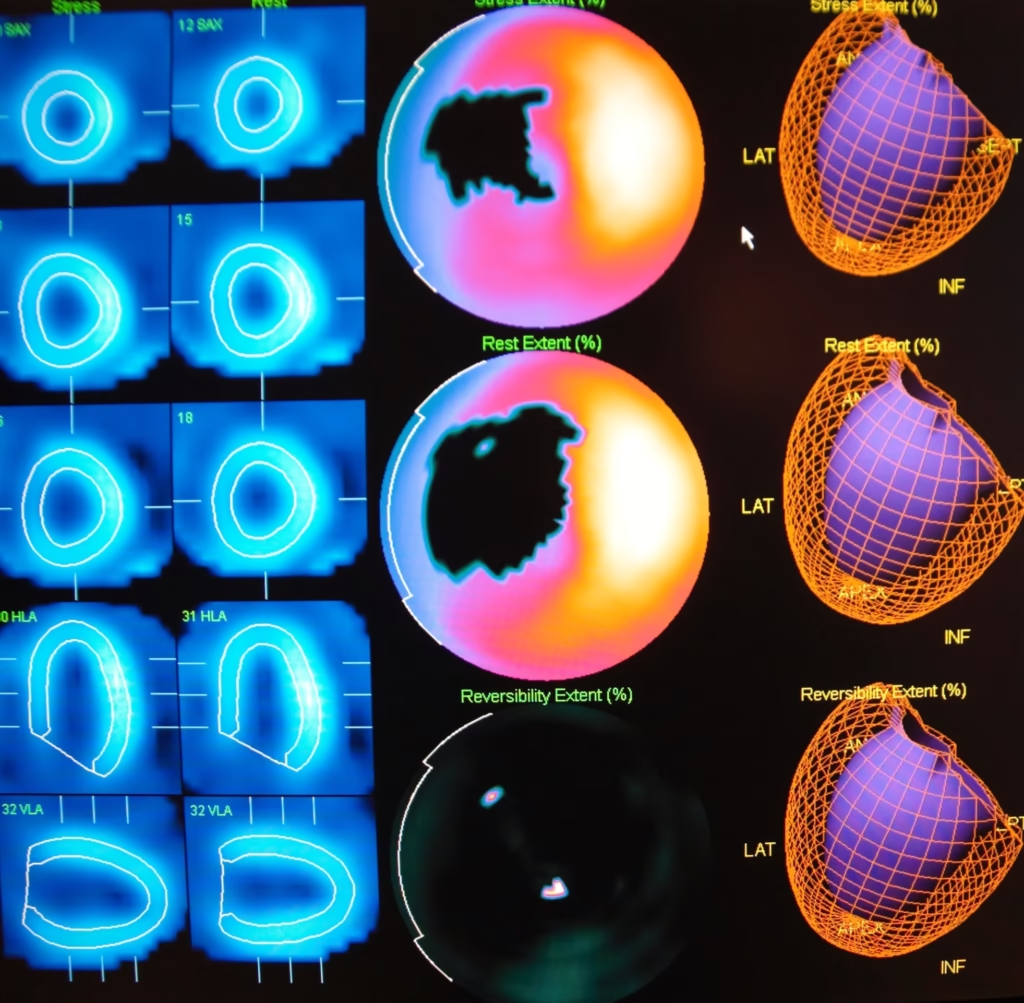

Fluorine-18 (18F) is a radionuclide of significant importance in the field of nuclear medicine, particularly in positron emission tomography (PET) imaging. With a half-life of approximately 109.77 minutes, 18F is ideal for diagnostic purposes due to its relatively short half-life, which reduces radiation exposure, and its ability to form compounds that are biologically relevant. The synthesis of Fluorine-18 involves a series of sophisticated chemical and nuclear reactions, demanding high levels of precision and control.

Production of Fluorine-18

Nuclear Reaction

Fluorine-18 is typically produced in a cyclotron through the bombardment of a target material with protons. The most common nuclear reaction used is the 18O(p,n) 18F reaction. This involves bombarding an enriched 18O-water target with high-energy protons (usually around 16-20 MeV), producing 18F.

18O + p → 18F + n

This process requires a cyclotron, a particle accelerator that propels protons to high velocities. When these protons collide with the 18O atoms in the water target, neutrons are knocked out, forming 18F. The enriched water target typically contains a high percentage of 18O to maximise the yield of 18F.

Targetry

The targetry system used for the production of 18F is crucial for efficient and safe synthesis. It involves a target holder that can withstand the high radiation and heat generated during the bombardment process. The holder is often made of materials like aluminium or silver, which are capable of handling the intense conditions. The enriched 18O-water is placed in this holder, and the entire system is cooled to manage the heat produced during the reaction.

Separation and Purification

Post-bombardment, the 18F produced needs to be separated from the target material and purified. This is often achieved using ion exchange chromatography. The target solution is passed through a column containing an anion exchange resin. 18F, being in the form of 18F− ions, is retained on the resin while the bulk of the water and other impurities pass through. The 18F is then eluted from the column using a suitable eluent, commonly potassium carbonate solution.

A table summarising the key properties of Fluorine-18:

| Property | Value |

| Symbol | 18F |

| Atomic Number | 9 |

| Mass Number | 18 |

| Atomic Mass | 18.0009380 u |

| Half-Life | 109.77 minutes |

| Decay Mode | Beta plus (β+) decay |

| Energy of Decay | 0.635 MeV (mean), 1.655 MeV (max) |

| Positron Range in Water | ~2.4 mm |

| Production Method | 18O(p,n) 18F reaction |

| Target Material | Enriched 18O-water |

| Applications | PET imaging, Radiopharmaceuticals |

Synthesis of Fluorine-18 Labelled Radiopharmaceuticals

The synthesised 18F is then used to produce 18F-labelled radiopharmaceuticals. The most widely known and utilised 18F-labelled compound is 18F-fluorodeoxyglucose (FDG), a glucose analogue used in PET imaging to detect metabolic activity.

Synthesis of 18F-FDG

The synthesis of 18F-FDG involves several steps:

- Nucleophilic Substitution Reaction: The process starts with the 18F ion reacting with a suitable precursor molecule. In the case of FDG, the precursor is typically mannose triflate. The 18F ion substitutes a leaving group (usually a triflate group) on the precursor molecule, forming 18F-FDG.

- Hydrolysis: The intermediate product obtained from the nucleophilic substitution is then hydrolysed to yield 18F-FDG. This step usually involves acid or base catalysis to remove protecting groups and convert the intermediate into the final radiopharmaceutical.

- Purification: The crude 18F-FDG is purified using high-performance liquid chromatography (HPLC) to remove any unreacted precursor and by-products. The purified 18F-FDG is then formulated into a sterile, pyrogen-free solution suitable for injection.

Automation in 18F Synthesis

The synthesis of 18F-labelled compounds, particularly 18F-FDG, has been highly automated to improve reproducibility, efficiency, and safety. Automated synthesis modules are widely used in radiopharmacies and PET centres. These modules handle the entire process, from the initial nuclear reaction to the final purification and formulation of the radiopharmaceutical. Automation minimises the risk of human error and exposure to radiation, making the production process safer and more efficient.

Quality Control

Quality control is a critical aspect of Fluorine-18 synthesis and involves several tests to ensure the final product’s purity, identity, and suitability for clinical use. Common quality control tests include:

- Radionuclidic Purity: Ensuring that the radioactivity is solely due to 18F, with no significant contamination from other radionuclides.

- Radiochemical Purity: Confirm that the 18F is present in the desired chemical form, such as 18F-FDG, and not in any other chemical species.

- Chemical Purity: Checking for the presence of any chemical impurities, including residual solvents and reagents.

- Biological Tests: Sterility and pyrogen testing to ensure the product is safe for human injection.

Regulatory Considerations

Various national and international guidelines regulate the production of 18F and 18F-labelled radiopharmaceuticals to ensure safety and efficacy. In the United States, the Food and Drug Administration (FDA) oversees the regulation of radiopharmaceuticals, while in Europe, the European Medicines Agency (EMA) provides guidelines. These regulations cover all production aspects, from the quality of the starting materials to the final product’s testing and clinical use.

Challenges and Innovations

While the synthesis of 18F and 18F-labelled compounds is well-established, several challenges remain. These include:

- Target Material Costs: Enriched 18O-water is expensive, making the production of 18F costly.

- Short Half-Life: The short half-life of 18F necessitates rapid synthesis, purification, and transportation to clinical sites.

- Radiation Safety: Ensuring the safety of personnel involved in the production process is paramount, given the high levels of radiation.

Innovations in the field aim to address these challenges. For instance, new target materials and methods to recover and reuse 18O-water are being developed to reduce costs. Additionally, advances in automation and miniaturisation of synthesis modules enhance efficiency and safety. Research into alternative methods of 18F production, such as direct fluorination techniques, is also ongoing, which could simplify the synthesis process.

Conclusion

The synthesis of fluorine-18 is a complex, multi-step process that requires sophisticated equipment and stringent quality control. The production begins with the cyclotron-based bombardment of enriched 18O-water to produce 18F, followed by its separation and purification. The purified 18F is then used to synthesise Fluorine-18 labelled radiopharmaceuticals, such as 18F-FDG, which are vital tools in PET imaging. Automation has significantly improved the efficiency and safety of 18F synthesis, and ongoing innovations continue to address the challenges in this field, ensuring that 18F remains a cornerstone of modern nuclear medicine.

Disclaimer

The content provided in this article is intended for informational and educational purposes only. Open Medscience does not provide medical, diagnostic, or therapeutic advice or services. The synthesis and handling of radioactive materials, including Fluorine-18, must be conducted by qualified professionals in licensed facilities, adhering strictly to all applicable regulatory and safety guidelines. Any procedures described herein are illustrative and should not be attempted without the appropriate expertise, authorisation, and infrastructure. Open Medscience assumes no liability for any misuse of the information presented or any consequences arising from its application.